Storing Onions & Garlic: Proper Ventilation

Jul 15, 2025 / btwgardenmachine/

Effective Ventilation Techniques for Long-Term Storage

Optimizing Airflow

Proper airflow is crucial for a healthy and comfortable indoor environment. Understanding the direction and velocity of air movement is key to maximizing ventilation effectiveness. This involves strategically positioning fans and vents to ensure even distribution of fresh air throughout the space. Identifying and addressing any obstructions to airflow, such as furniture or clutter, will significantly improve the overall ventilation process. By allowing air to circulate freely, you can effectively remove stale air and pollutants, leading to a more pleasant and breathable environment.

Consider using fans to create a gentle breeze. Properly placed fans can effectively circulate air and prevent stagnant pockets of air from forming, thereby improving the overall ventilation. A balanced and consistent airflow is vital for maintaining a comfortable temperature and humidity level in the area.

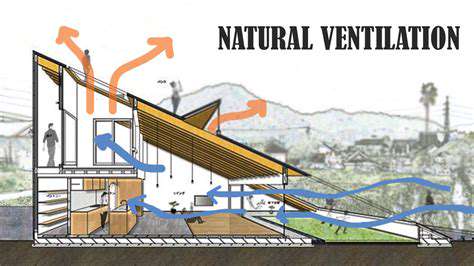

Implementing Natural Ventilation Strategies

Natural ventilation methods, such as utilizing windows and doors, are often more energy-efficient and cost-effective than mechanical systems. Careful consideration of the building's orientation and local climate conditions is essential for optimizing natural ventilation. Opening windows and doors during periods of favorable weather conditions can significantly improve the indoor air quality. Properly designed windows and openings can allow for cross-ventilation, which enhances the exchange of fresh air with the outside environment.

Maximizing natural light can also enhance ventilation. Natural light promotes better air circulation and contributes to a more pleasant environment. By strategically positioning windows and doors, you can effectively utilize natural airflow to improve ventilation and reduce reliance on mechanical systems.

Choosing the Right Ventilation Equipment

Selecting appropriate ventilation equipment is essential for maintaining an effective and efficient ventilation system. Different types of ventilation equipment, such as exhaust fans and air purifiers, serve various purposes. Understanding the specific needs of the space and the desired outcomes will help you choose the most suitable equipment. Consider factors like the size of the area, the level of air pollution, and the desired air quality when selecting ventilation equipment. This careful consideration will ensure that the chosen equipment effectively addresses the ventilation needs of the specific environment.

Understanding the different types of fans and their capabilities is crucial. Knowing the differences between centrifugal fans, axial fans, and other types of fans is essential to selecting the appropriate equipment for your specific application. Each type of fan has unique characteristics that influence its performance and suitability for different ventilation needs.

Maintaining Ventilation Systems

Regular maintenance of ventilation systems is essential for optimal performance and longevity. Preventive maintenance, such as cleaning filters and inspecting components, can prevent breakdowns and ensure smooth operation. Routine maintenance is also crucial to maintain a clean and healthy environment. By regularly cleaning ventilation components, you can keep the system working effectively and prevent the buildup of pollutants and dust.

Addressing any malfunctions promptly is crucial. Identifying and resolving issues quickly can prevent the worsening of problems, leading to more significant repairs. Prompt attention to minor issues can save you significant time, money, and effort in the long run.

Understanding Ventilation Requirements

Understanding the specific ventilation requirements of different spaces is key to designing and implementing effective ventilation systems. Different environments, such as kitchens, bathrooms, and industrial settings, have unique ventilation needs. Careful consideration of these specific needs ensures that the ventilation system meets the requirements for a healthy and safe environment. Understanding these requirements will enable you to design a system that effectively removes pollutants and maintains a healthy indoor air quality.

Consider factors like humidity levels, air quality concerns, and potential hazards when determining ventilation needs. This ensures the system is adequately equipped to address the unique demands of the area, promoting a healthy and safe environment for all occupants.

Additional Tips for Maintaining Freshness

Prioritizing Regular Maintenance

Regular maintenance is crucial for preventing costly repairs and ensuring your equipment functions optimally. This involves more than just occasional checks; it necessitates a structured schedule that includes inspecting all components, identifying potential issues before they escalate, and addressing them promptly. Consistent maintenance routines are key to extending the lifespan of your equipment and minimizing downtime. Failing to adhere to a regular maintenance schedule can lead to significant problems down the road.

A well-defined maintenance plan should include specific tasks, timelines, and responsibilities. This will ensure that everyone involved understands their role in keeping equipment in top condition. Detailed records of maintenance activities are vital for tracking performance trends, identifying recurring issues, and proactively implementing preventative measures. This proactive approach will ultimately save time and money.

Understanding Equipment Specifications

Thorough knowledge of your equipment's specifications is essential for proper operation and maintenance. This includes understanding its capacity limits, operating parameters, and any specific safety precautions. Familiarity with these details allows you to operate within safe boundaries, maximizing efficiency and preventing potential damage. Understanding the intricacies of your equipment will greatly enhance your ability to maintain it effectively.

Consult the equipment's manuals and technical documentation for detailed information. These resources will provide valuable insights into the equipment's design, function, and maintenance requirements. By understanding these specifications, you can ensure that your equipment is used correctly and maintained to its highest potential.

Implementing Preventative Measures

Implementing preventative measures is a crucial aspect of maintaining equipment. These measures include regular inspections, cleaning, lubrication, and adjustments to ensure everything functions smoothly and efficiently. By proactively addressing potential issues, you can prevent costly breakdowns and downtime. Preventative measures are far more cost-effective than reactive repairs.

Identifying potential wear and tear on equipment components is a key part of preventative maintenance. This involves regularly inspecting for signs of damage, corrosion, or unusual sounds or vibrations. Early detection of potential problems will allow for timely intervention and avoid costly repairs or replacements.

Addressing Routine Maintenance Tasks

Routine maintenance tasks are essential to keep your equipment in good working order. These tasks include cleaning components, lubricating moving parts, checking fluid levels, and ensuring proper alignment. These seemingly small tasks can prevent major problems if addressed regularly. Skipping routine maintenance can lead to costly and time-consuming repairs down the line.

Training and Skill Development

Investing in the training and skill development of your maintenance team is crucial for maintaining equipment effectively. This includes providing comprehensive training on the specific equipment you use and the necessary maintenance procedures. A well-trained workforce is more efficient and can identify potential problems more quickly, resulting in fewer costly repairs and improved equipment longevity. A skilled maintenance team is a valuable asset to any organization.

Safety Protocols and Procedures

Prioritizing safety is paramount when maintaining equipment. This involves adhering to all safety protocols and procedures, including wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and ensuring a safe working environment. Ignoring safety protocols can lead to severe injuries and accidents. Safety should always be the top priority in any maintenance activity.

Regular safety training for all personnel involved in maintenance activities is essential. This training should cover potential hazards associated with specific equipment, proper handling techniques, and emergency procedures. This will minimize the risk of accidents and ensure a safe working environment for everyone.